FACTORY &

TECHNOLOGY OVERVIEW

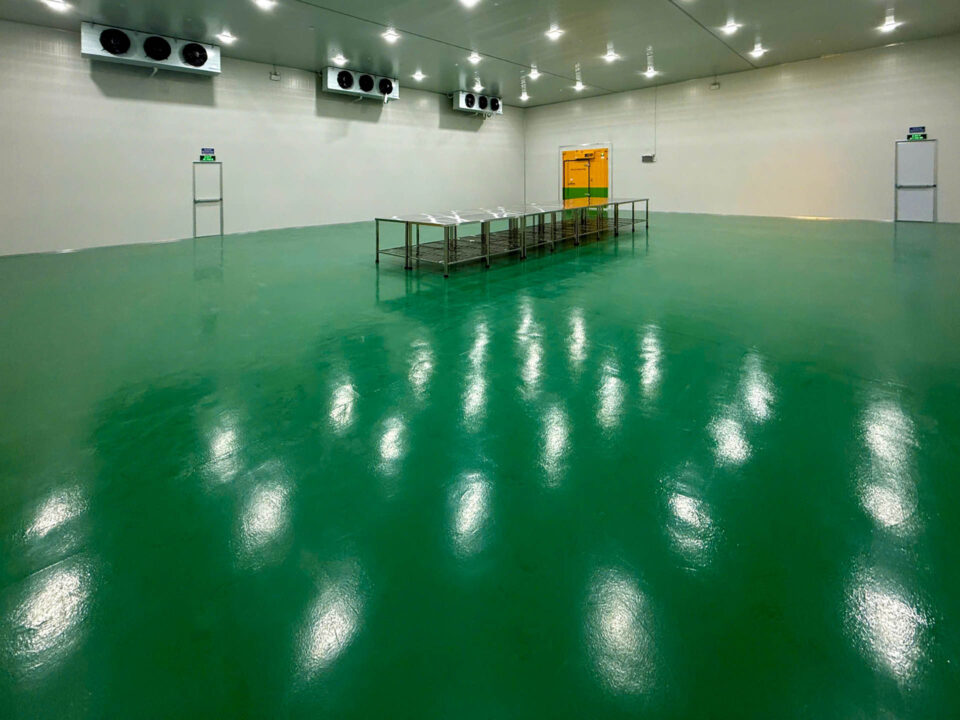

Hai Trieu Agri Co., Ltd operates a strategically located fruit treatment facility near major farming areas in Tien Giang, Long An, and Ben Tre. Spanning over 5,000 m², the factory is built to meet strict food safety and environmental standards and is designed for closed-loop operations.

We apply Vapor Heat Treatment (VHT) technology to eliminate quarantine pests such as fruit fly eggs and larvae, ensuring strict phytosanitary safety for export markets. The entire process is closely monitored with full traceability, complying with regulations in Japan, Korea, Australia, and other high-standard markets.

Technology Overview

Vapor Heat Treatment (VHT) Systems

We have invested in modern Vapor Heat Treatment (VHT) systems imported from Japan – a mandatory technology for fresh fruit exports to premium markets. The VHT process eliminates insects and eggs without chemicals, preserving the fruit’s natural appearance and internal quality.

Key Infrastructure

Includes

- VHT chambers with a capacity of ~5 tons/shift.

- Separate zones for receiving – pre-processing – sorting – packing.

- Cold storage areas for pre- and post-treatment preservation.

- Quality inspection room and sampling station for quarantine clearance.

Additionally, the factory features automated monitoring systems for temperature and humidity, ensuring full quality control for each batch.

Postharvest Treatment Process (VHT)

Applicable for fresh fruits such as mango, dragon fruit, pomelo, etc., intended for export

Receiving and Sorting

Fruits are sourced directly from certified growing areas (e.g. VietGAP or GlobalG.A.P).

Preliminary inspection is conducted to ensure freshness, no bruising, no pests or diseases.

Fruits are sorted by size, ripeness, and in accordance with the requirements of the target export market.

Washing and Cleaning

Fruits are washed with clean water using vibrating conveyors and high-pressure spray nozzles.

This process removes dirt, latex, debris, and any pesticide residues.

Depending on the fruit type, additional sanitizing steps using approved solutions may be applied.

Vapor Heat Treatment (VHT)

Fruits are placed in VHT chambers where temperature and humidity are precisely controlled.

Typical treatment involves heating to 46°C to 48°C for about 30–60 minutes, depending on the fruit.

The objective is to eliminate fruit fly eggs, larvae, and other quarantine pests to meet phytosanitary export standards.

Cooling and Drying

After heat treatment, fruits are cooled using ambient or forced air to return to normal temperature.

Surface drying is carried out using fans to prevent moisture-related damage during packaging and transport.

Packaging

Fruits are packed in export-grade materials such as ventilated cartons, PE bags, or as per specific market requirements.

Each package is labeled with traceability QR codes, VHT treatment marks, and export stickers.

Storage and Transportation

Products are stored at appropriate temperatures (typically between 10°C and 15°C).

Transportation is done using refrigerated trucks to maintain the quality of fresh fruits until delivery or export.